The game of golf has been around for centuries,

And throughout its history, the golf ball has undergone significant changes in design and material. From the early days of golf, when players used wooden balls, to the modern-day designs that are made of multiple layers of materials, the evolution of golf balls has been an interesting one.

In the early days of golf, the balls were made of wood. They were often made from hardwoods like beech or boxwood and were typically handcrafted by skilled craftsmen. These wooden balls were relatively small and hard, making it difficult for players to control their shots. They were also prone to cracking, which made them ineffective after just a few rounds of play.

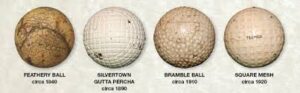

In the 17th century, golfers began experimenting with a new material for their balls – feathers.

These balls, known as featheriness, were made by stuffing wet goose feathers into a leather pouch. The pouch was then sewn shut, and the ball was left to dry. Once dried, the ball would be painted and polished to create a smooth surface. These featheriness were much more effective than the wooden balls of the time, as they were larger, softer, and more aerodynamic, giving golfers more control over their shots.

The next major development in golf ball design came in the mid-1800s when a new material called gutta-percha was discovered. Gutta-percha is a natural rubber that is harvested from the sap of the gutta-percha tree, which is native to Malaysia. Golf ball manufacturers found that gutta-percha was an ideal material for making golf balls because it was tough, durable, and could be molded into different shapes. Gutta-percha balls were also cheaper to produce than featheriness, making them more accessible to the masses.

Gutta-percha balls were a significant improvement over featheriness,

But they still had some limitations. They were hard and did not compress easily, which made them difficult to control on short shots. To solve this problem, manufacturers began experimenting with different types of cores for their gutta-percha balls. In 1898, the first rubber-cored ball was introduced, and it quickly became popular among golfers.

Rubber-cored balls were made by wrapping a layer of rubber around a small core of compressed cork. This design made the ball more responsive and allowed it to compress more easily on impact, giving golfers more control and distance on their shots. The new design also made the balls more durable, as they were less likely to crack or split during play.

Over the next few decades, golf ball manufacturers continued to refine the design of their rubber-cored balls. They experimented with different types of rubber, different core materials, and different cover materials. In the 1930s, a new design known as the wound ball was introduced. Wound balls were made by winding a long strand of rubber around a small core of compressed cork. The rubber was then covered with a layer of balata, a type of rubber that was similar to gutta-percha but more durable.

Wound balls were a significant improvement over earlier designs,

As they provided even more distance and control on shots. They also had a soft feel that many golfers found appealing. However, they were also more expensive to produce than other types of balls, making them less accessible to the masses.

In the 1960s, golf ball manufacturers began experimenting with new materials and designs in an effort to create a ball that would provide even more distance and control. The result was the two-piece ball, which is still the most popular type of ball used by golfers today.

Two-piece balls are made by molding a large core of solid rubber, then covering it with a layer of hard plastic or resin. This design allows the ball to travel further and faster

than previous designs, while still providing good control and feel on shots.

The hard cover also makes the ball more durable, so it lasts longer than previous designs. Two-piece balls are also less expensive to produce than wound balls, making them accessible to golfers of all levels.

In the 1990s, golf ball manufacturers introduced a new design called the multi-layer ball. These balls have a soft core surrounded by layers of progressively harder materials. The outermost layer is made of a thin cover material, which provides the ball with a soft feel and good spin control on shots. The inner layers provide the ball with added distance and control, as well as improved durability.

Multi-layer balls are popular among professional golfers because they offer a combination of distance and control that is unmatched by other types of balls. They also provide a soft feel that many golfers find appealing. However, they are more expensive to produce than two-piece balls, so they are not as accessible to the average golfer.

In recent years, golf ball manufacturers have continued to refine their designs,

Using new materials and technologies to create balls that provide even more distance, control, and durability. One of the latest innovations is the use of urethane covers, which provide a soft feel and good spin control on shots. Urethane covers are also more durable than previous cover materials, so they last longer.

Another recent innovation is the use of dimple patterns to improve the aerodynamics of golf balls. Golf balls have been dimpled for over a century, but recent advances in computer modeling and design have allowed manufacturers to create more efficient dimple patterns that reduce drag and increase lift, resulting in longer and straighter shots.

In conclusion,

the evolution of golf balls from the early days of wooden balls to modern-day multi-layer designs has been an interesting and ongoing process. Golf ball manufacturers have continually experimented with new materials and designs in an effort to create balls that provide golfers with more distance, control, and durability. From the early featheriness and gutta-percha balls to the modern-day multi-layer balls, each new design has improved on the previous one, providing golfers with better performance and a more enjoyable game. As technology continues to advance, it will be interesting to see what new designs and materials golf ball manufacturers come up with next.